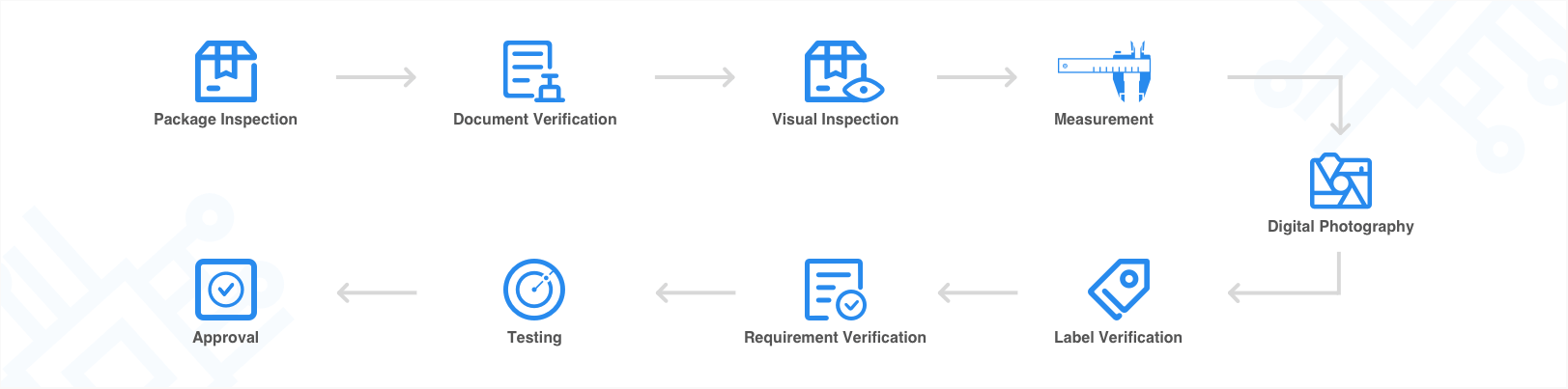

Inspection Process

Our inspection process reflects our systems-based approach to quality.

We inspect, measure, verify, and test electronic components from the outer packaging inward to confirm that they meet the highest standards.

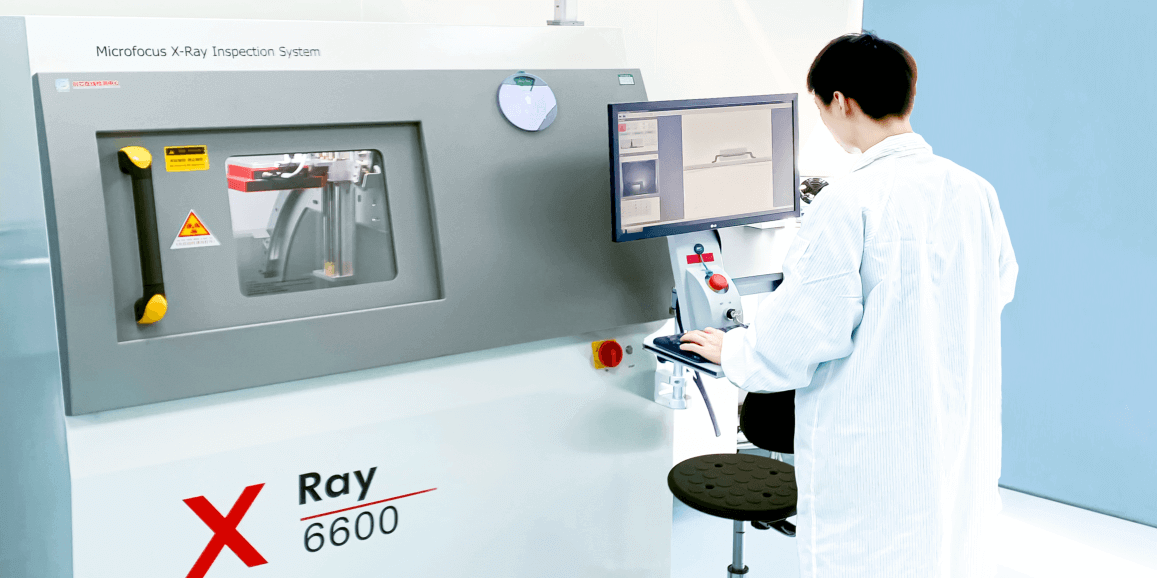

Professional Equipments

X-ray Detector

X-ray detector uses low-energy X-rays without damaging the inspected item to quickly detect the inspected object.

Ultrasonic Scanning Microscope

Water immersion ultrasonic scanning microscope is perfect fit detection chip internal packaging defects.

Testing Capacities

JOWIN’s in-house testing laboratories are fully equipped with the industry’s most advanced functionality and authenticity verification tools to manage custom testing programs for any project.

Functionality Testing

JOWIN’s functionality lab can test the full range of electronic components and peripherals to ensure they are fully functional. We offer a range of tests to determine components’ quality, capacity, output, value, and more

Authenticity Testing

Our counterfeit detection testing lab is provisioned with the most advanced in-house tools to verify component authenticity. With destructive, nondestructive, and custom testing solutions available, the integrity of your parts will never be in question.

Custom Testing

We offer custom functionality testing for components and consumer electronics, from full-unit to component-level.

Explore Our Facilities

JOWIN maintains strict environmental controls at our global operational facilities. We protect your products across all stages of the supply chain.